Contact our boss directly.

Don’t wait — our boss replies within 20 minutes to all inquiries.

Submit your question now and get professional feedback, accurate pricing, and technical advice — fast.

Key Takeaways

- PE sintered filters are mechanically tough in the real world—shock, vibration, and handling abuse are where they often shine.

- “Harsh environment” usually means pressure pulses + abrasion + heat + chemistry happening at the same time. That combo is what kills filters.

- Durability isn’t just material choice—it’s pore structure, wall thickness, support strategy, and housing design.

- The most common failures are boring but brutal: creep, stress cracking, surface blinding, and abrasive wear.

- If you want PE to survive, spec it like a grown-up: flow + ΔP + temperature + contaminant type + cleaning method. Not just “10 micron, please.”

If you want the honest answer: polyethylene (PE) sintered filters are durable in harsh environments when the “harsh” part is mechanical abuse—vibration, bumps, pressure fluctuations, and gritty solids—and when the temperature and chemical exposure stay within sane limits. Their rigid porous structure and impact tolerance often outperform delicate media designs. But PE isn’t invincible: sustained heat + high differential pressure can trigger creep, aggressive solvents can cause swelling or stress cracking, and abrasive slurries can slowly sandblast pore openings. Durability comes from the whole design—material, geometry, and operating conditions—not the polymer name on a datasheet.

Alright. Now let’s talk about the ways filters actually die.

People hear “harsh” and immediately picture a beaker of acid bubbling like a villain’s lair.

Sometimes, sure. But in industry, harsh usually looks like this:

And the most dangerous harsh environment? The one where two or three of those pile up together.

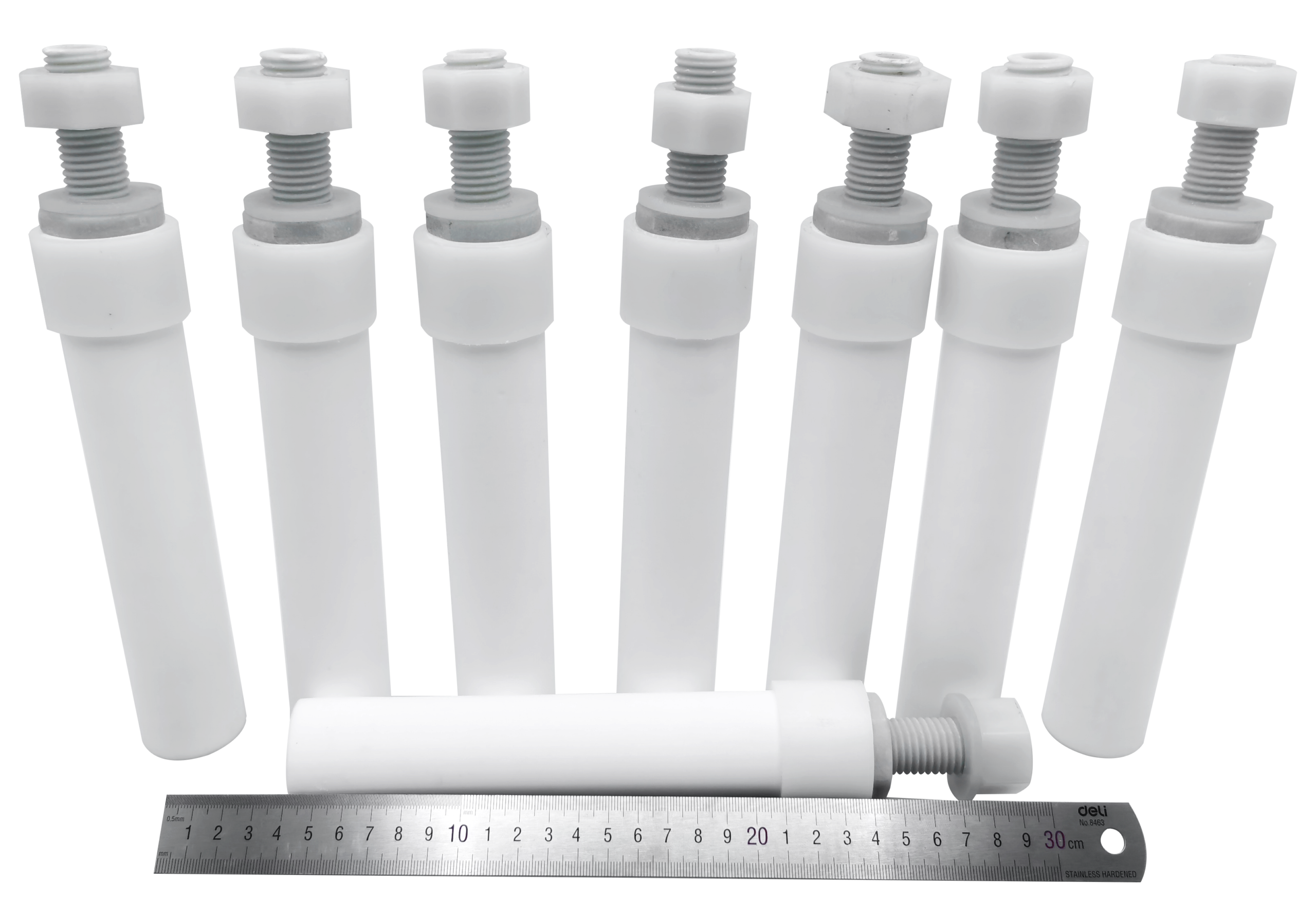

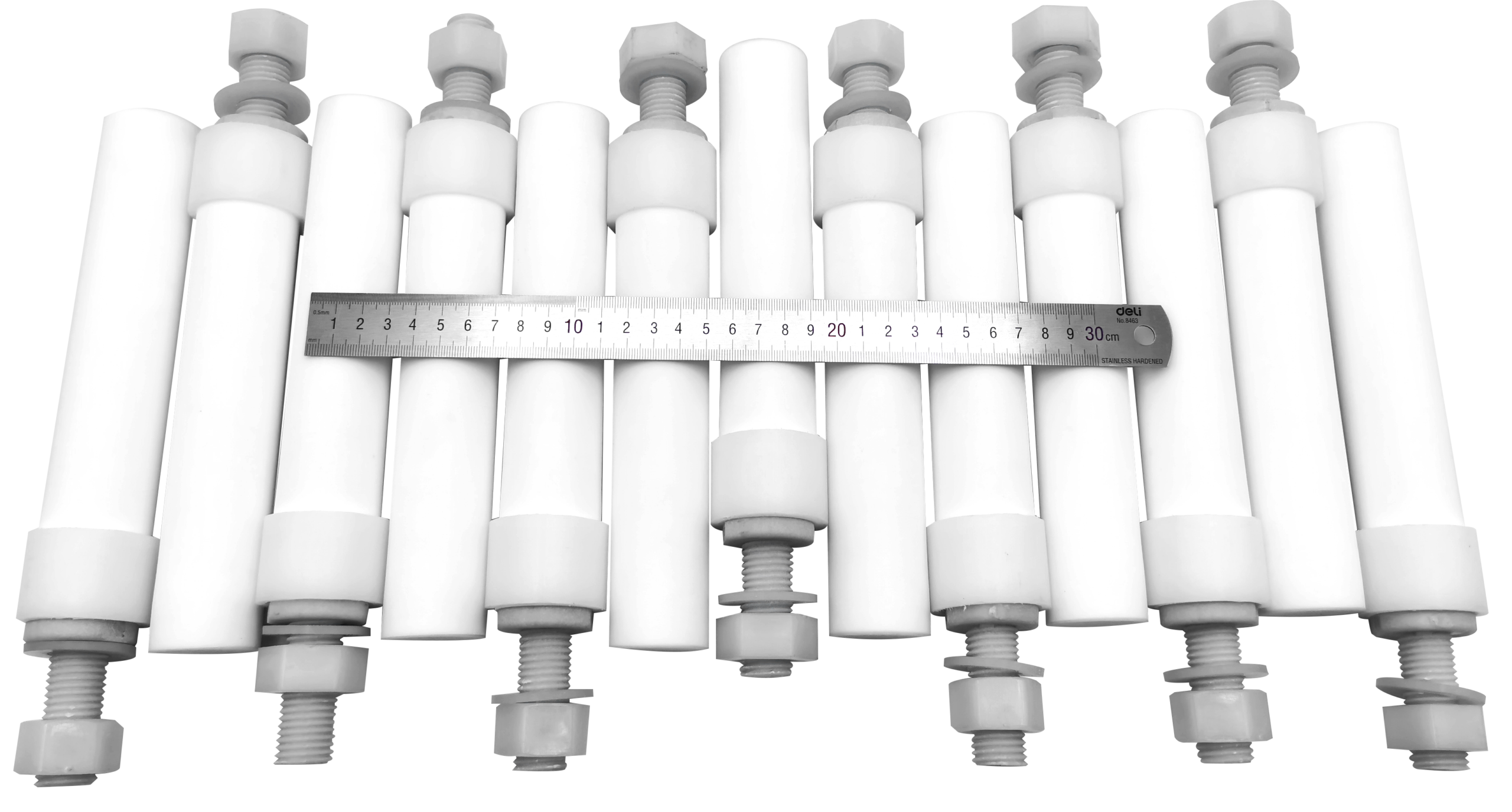

A sintered PE filter is basically fused polyethylene powder: particles bond at contact points, creating a rigid network of interconnected pores.

That structure gives you a few durability perks that don’t get enough credit:

I honestly believe this is why PE keeps showing up in “I need something that won’t baby-sit itself” applications.

If your filtration system lives on a skid with a pump that sounds like it’s chewing gravel, PE can be a very rational choice.

Why PE holds up:

What to watch:

ΔP is the tax your system pays for filtration. Too high, too long, too often—and things start deforming.

In harsh conditions, ΔP isn’t steady. It spikes. It drops. It spikes again. That cycling is where long-term durability gets decided.

PE durability risk at high ΔP:

If you only remember one phrase, make it this: heat + ΔP + time = creep country.

Abrasive solids don’t clog politely. They erode.

Common abrasive offenders:

How PE behaves:

If you’re filtering abrasive slurry, durability isn’t just “will it break?” It’s “will it still filter correctly after 6 months of getting sandblasted?”

PE can be excellent in many aqueous, mild chemical environments. But harsh solvents, strong oxidizers, and certain surfactant cocktails can make life interesting.

Typical chemical durability pitfalls:

And yes—CIP chemicals count as “chemical exposure.” Food-grade doesn’t mean polymer-friendly.

Symptoms:

Why it happens:

How to reduce risk:

Symptoms:

Why it happens:

How to reduce risk:

Symptoms:

How to reduce risk:

Blinding is when the surface loads up and stops letting flow through. It’s not “damage,” but it drives ΔP up, which creates damage.

Typical causes:

Fix:

A uniform pore structure is simple and predictable. A gradient structure can capture larger particles first and reduce early surface blinding.

If your harsh environment includes spiky solids loads, gradient designs can be a lifesaver.

Durability is often a math problem dressed up as a product.

I’ve watched perfectly good filters “fail” because the housing was basically a booby trap:

If you want durability, treat the housing like part of the filter. Because it is.

You don’t need a million-dollar lab to learn a lot. You need discipline.

1) Baseline performance

2) Abuse it like the real system

3) Measure drift

4) Post-mortem

If the filter “passes” only when treated gently, it didn’t pass. It auditioned.

Yes—especially for mechanical harshness like vibration, pressure pulses, and handling abuse, as long as temperature and chemical exposure stay within appropriate limits. Durability depends heavily on design and operating conditions.

Common causes include creep under sustained ΔP at elevated temperature, stress cracking from chemical exposure plus mechanical load, and abrasive wear in gritty slurries. Surface blinding can also drive ΔP high enough to trigger structural issues.

They can, but abrasion may gradually change pore geometry and performance. For highly abrasive slurries, staged filtration and lower face velocity can extend life significantly.

They can. Repeated exposure to incompatible chemicals—especially at elevated temperatures—can increase the risk of swelling, stress cracking, or surface property changes. Cleaning should be validated, not assumed.

Choose PP or PTFE when chemical resistance and temperature demands exceed PE’s comfort zone. PTFE is often preferred for aggressive solvents and harsh chemistry; PP covers many industrial chemicals at a strong cost/performance balance.

If you’re asking about durability, you’re already ahead of most buyers—because the cheapest filter is the one that doesn’t create a maintenance soap opera.

PE sintered filters can be impressively durable in harsh environments, but only if you respect the real stressors: ΔP cycling, heat, abrasion, and cleaning chemistry. Get those right—and PE can run like a reliable old truck. Ignore them—and even the toughest polymer will eventually wave a white flag.

If you share your Internal Links JSON, I’ll add the required 5–8 exact anchor links cleanly. And if you tell me what “harsh” means in your customer’s world (abrasive slurry? pump pulses? solvent washdowns?), I can tailor the examples so the post reads like it came from the plant floor, not from a keyboard.