Contact our boss directly.

Don’t wait — our boss replies within 20 minutes to all inquiries.

Submit your question now and get professional feedback, accurate pricing, and technical advice — fast.

Key Takeaways

- PE sintered cartridges improve efficiency by stabilizing flow and pressure drop (ΔP)—less “mystery clogging,” fewer production tantrums.

- Their rigid porous structure supports repeatable filtration across batches, especially for water-like streams and pre-filtration.

- In the right applications, they extend run time via depth filtration (capturing particles inside the pore network, not just on the surface).

- They can fit hygienic operations when paired with proper housing design + cleaning validation—the cartridge is only half the hygiene story.

- The fastest way to waste money is to spec by micron rating alone. Efficiency depends on pore distribution, thickness, flow, and your product’s “gunk personality.”

If you’re in food processing, you already know the villain. It’s not bacteria in a lab coat twirling a mustache. It’s downtime—that slow, expensive bleeding of minutes and batches while someone mutters, “The filter’s plugged again.”

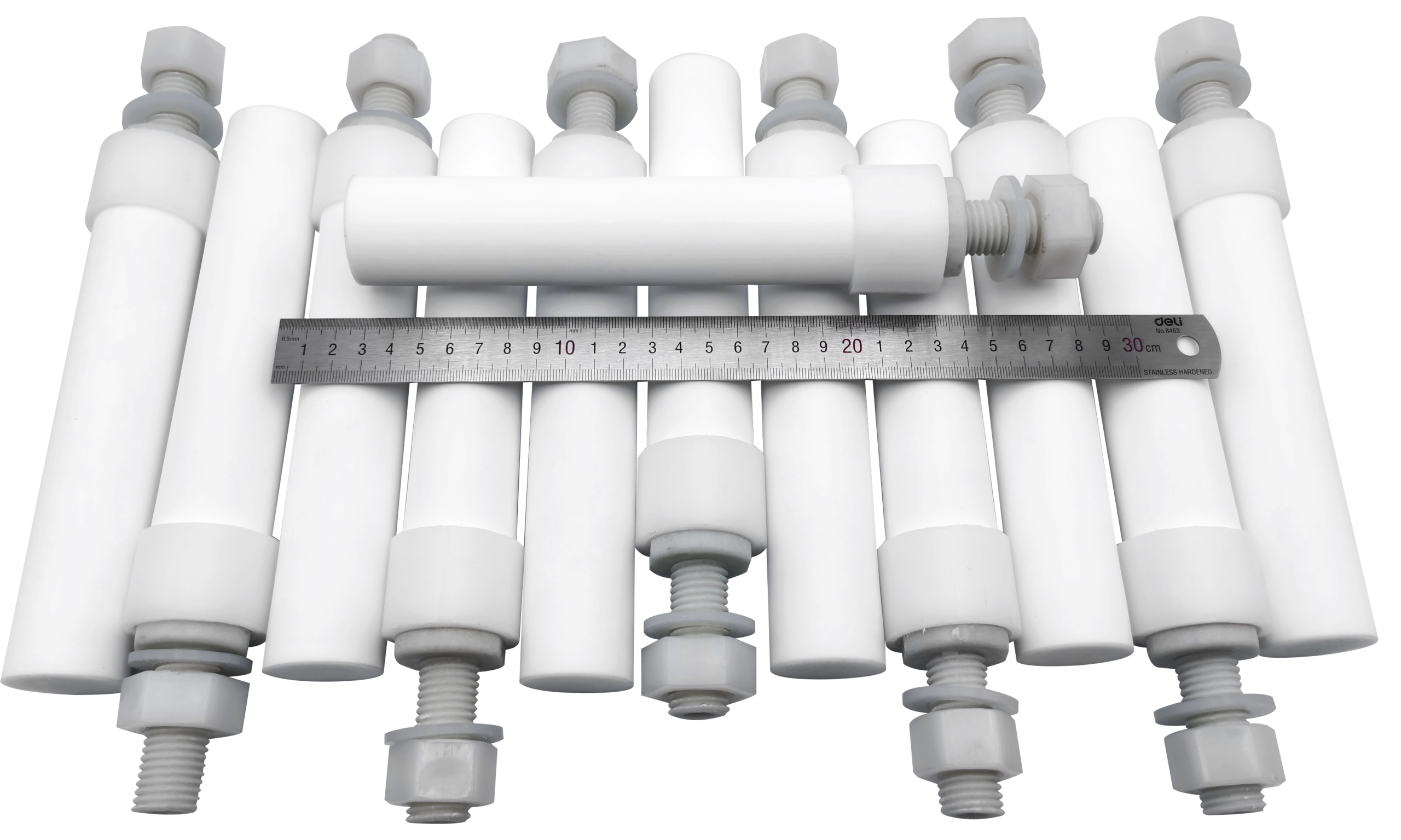

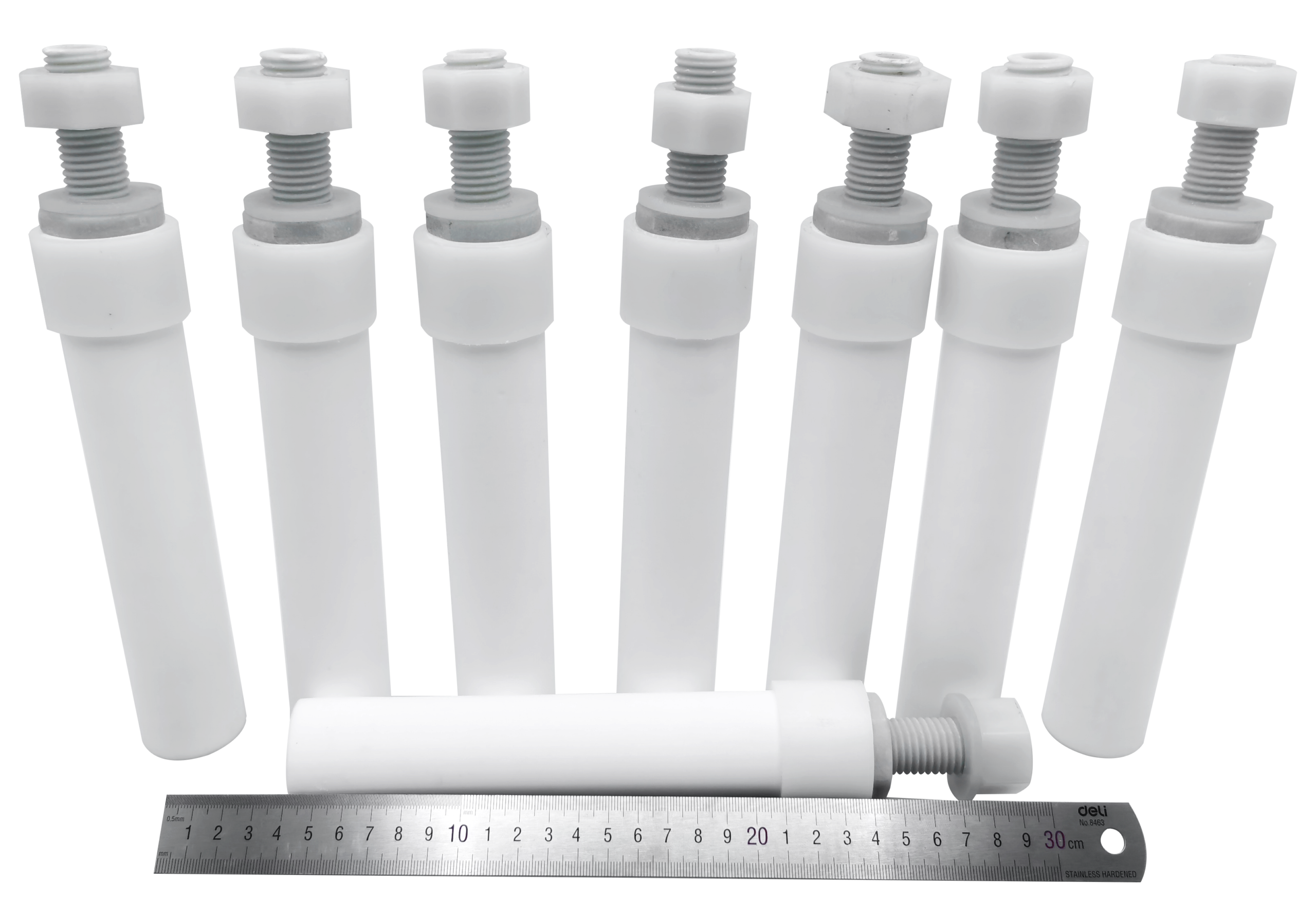

So how do PE sintered filter cartridges improve filtration efficiency in food processing? Simple: they give you predictable flow, stable pores, and depth capture that can run longer before ΔP spikes—especially in pre-filtration, water systems, brine, syrups (depending on viscosity), and process utilities. Done right, they reduce changeouts, smooth out batch-to-batch variation, and help you hit quality targets without turning your line into a stop-and-go traffic jam.

Let’s get practical. Not brochure-practical. Real-plant practical.

People love to throw around the word “efficiency” like it’s a magical spice you can sprinkle on a process. In food processing, filtration efficiency usually boils down to four brutally measurable things:

A filter that captures particles but kills flow is not “efficient.” It’s a very expensive plug.

A sintered PE cartridge is a self-supporting porous body. It doesn’t rely on a delicate pleat pack or a soft fibrous mat to keep its shape.

That rigidity matters because food plants don’t run under “perfect laminar flow, no pressure pulses, everyone gentle.” They run under:

Rigid structure = fewer surprises.

Here’s the mental model I use:

PE sintered cartridges, in many cases, behave like that maze. For certain particulate profiles—especially fine but non-sticky solids—they can extend run time and reduce the “change filter every time the line sneezes” routine.

Food plants live on repeatability. If batch A flows at 60 L/min and batch B crawls at 35 L/min with the same cartridge, you get:

A well-specified PE sintered cartridge can help stabilize filtration behavior across shifts and batches—especially when the upstream solids load isn’t wildly swinging.

Let me be blunt: no filter is “hygienic” by itself. Hygienic design is a system property.

PE sintered cartridges can support hygienic processing because they’re:

But if your housing has dead legs, poor drainage, or seals that trap product, your “hygienic filter” becomes a very expensive petri dish.

This is the “quiet win” category. Filtration efficiency often improves most when you stop letting utility streams sabotage everything downstream.

PE sintered cartridges can be useful for:

If you’re filtering brine or mild aqueous solutions, PE can deliver steady performance—especially when you need a rugged element that won’t crumble under frequent maintenance cycles.

Sugar syrups get tricky because viscosity is the boss. PE can still work, but your ΔP math must be honest.

This is where efficiency becomes a domino effect. A PE sintered cartridge upstream can protect:

Protecting expensive downstream filtration is one of the most financially attractive uses of PE sintered elements.

If you take nothing else, take this: “10 micron” is not a complete specification.

You need:

A “5 micron” cartridge running at the wrong flow is like using a coffee filter to strain soup. You’ll get something, but not what you want.

Food streams are weird. They’re not just “liquid + particles.” They’re:

Depth filters love certain solids. They hate others. Sticky, gelatinous, or smear-prone contaminants can blind pores quickly. That’s not a PE problem; that’s physics again, showing up uninvited.

CIP is powerful—when it’s validated. But I’ve seen plants assume CIP “cleans everything,” while the filter slowly accumulates a private museum of residues.

If you plan to reuse cartridges:

If you don’t validate, you’re not cleaning—you’re just rinsing with confidence.

Answer these, and material selection becomes science, not superstition.

I honestly believe pilot testing is the most underused superpower in filtration. Even a small trial run measuring:

…will save you months of guesswork and a stack of disappointed purchase orders.

They improve efficiency by delivering stable pore structure, enabling depth capture, and maintaining more predictable flow and ΔP behavior in suitable streams—reducing changeouts and protecting downstream filtration.

They can be used in food processing systems, but suitability depends on the exact PE grade, regulatory requirements, and system design. Always confirm material compliance with your local food-contact regulations and your plant’s validation standards.

Often, yes—within compatibility limits. CIP success depends on soil type (fats/proteins/starches), cleaning chemistry, temperature, and time. If allergens are involved, cleaning must be validated, not assumed.

There’s no universal “best.” It depends on the contaminant and downstream equipment sensitivity. Select based on the particle removal target, then validate via flow rate and ΔP behavior under real operating conditions.

Choose PP or PTFE when your stream has more aggressive chemistry or higher temperatures. PTFE is the go-to for harsh chemicals; PP is a strong general-purpose option for many industrial fluids.

PE sintered filter cartridges can absolutely boost filtration efficiency in food processing—but not because they’re magical. They win because they’re predictable, tough, and structurally suited to stable, repeatable filtration—especially in utility streams and pre-filtration roles that quietly decide whether your line runs smooth or stutters like an old engine.

If you paste your Internal Links JSON, I’ll rework this post with 5–8 exact keyword links placed naturally, plus I can tailor sections to your specific sub-industry (dairy, beverage, brewing, edible oils, sauces, confectionery) so it feels like it was written by someone who’s actually watched a filler line stop mid-shift.