Contact our boss directly.

Don’t wait — our boss replies within 20 minutes to all inquiries.

Submit your question now and get professional feedback, accurate pricing, and technical advice — fast.

Harsh chemicals don’t just damage product quality—they quietly chew up pumps, valves, and sensors. PTFE sintered filter cartridges act like a rugged “front-line shield,” stopping particles and surviving solvents that ruin other media.

Nylon (PA) sintered filter cartridges are the “work boots” of porous plastics—tough, efficient, and surprisingly versatile. Here’s how they perform, where they shine, and how to choose the right spec without buying problems.

PP can handle heat better than most people expect—until ΔP, time, and mechanical stress turn “high temperature” into “high regret.” This guide explains where PP sintered cartridges truly work at elevated temperatures, where they don’t, and how to spec them so they survive.

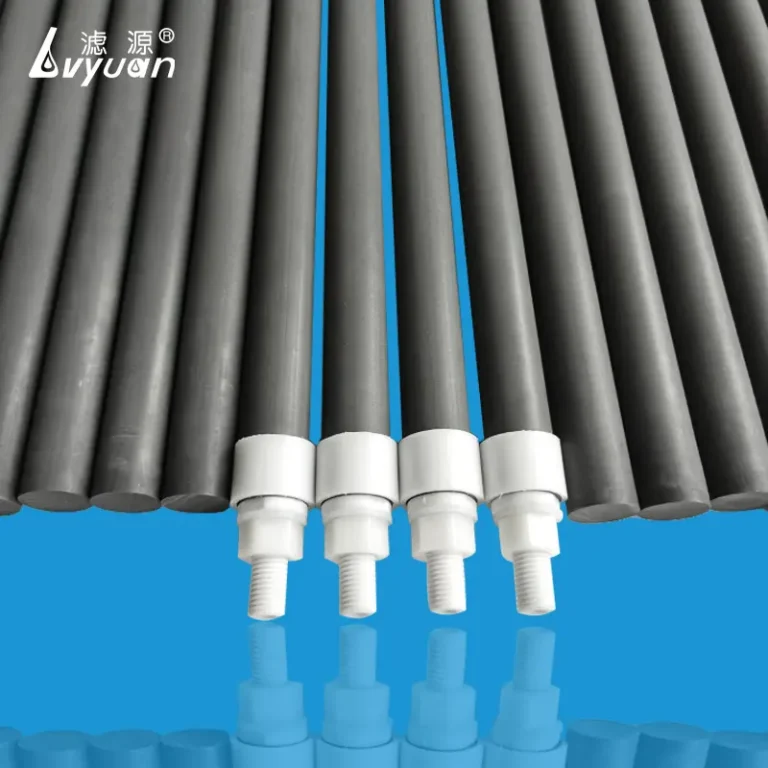

Harsh environments don’t break filters politely—they grind them down, swell them up, or crack them at the worst time. Here’s a practical, field-tested way to judge how durable PE sintered filters really are, what kills them, and how to spec them to survive.

PE sintered filters don’t get the spotlight like PTFE, but they quietly win in real factories: tough, consistent, cost-smart, and easy to integrate. This guide breaks down where PE shines, where it doesn’t, and how to spec it so it behaves in production.